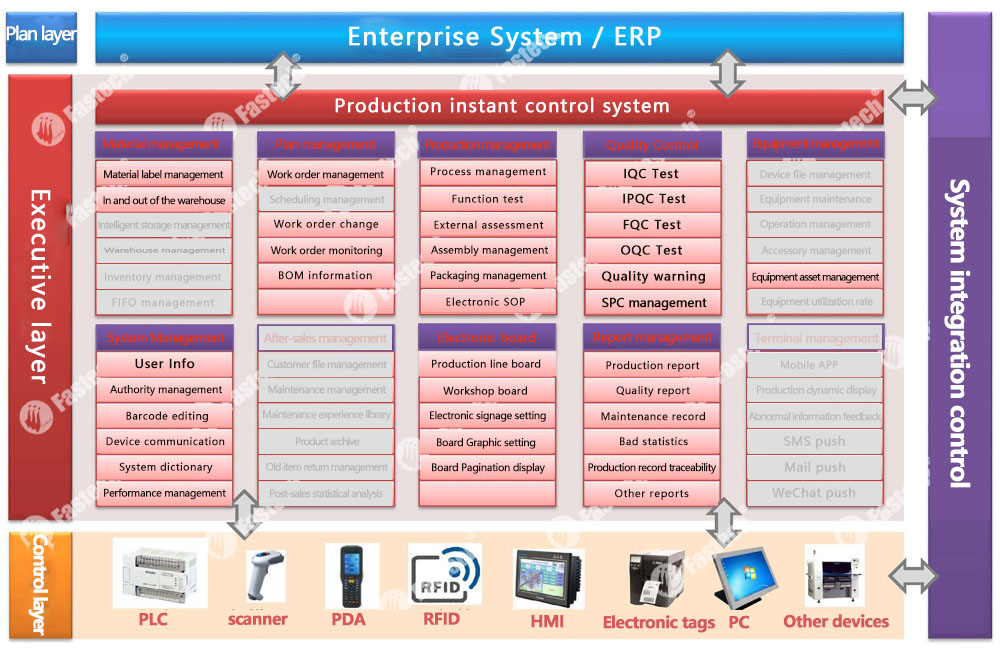

Production instant control system

一、What is the sfis system?

SFIS system is a system that can master the situation of production site and give feedback information to managers in time, so as to effectively control the production site.It has management functions such as error prevention, resource tracking and real-time analysis.

二、SFIS Functional features

1.Production process record and trace

SFIS system records all the production process from raw material entering into the factory to finished product warehousing, the materials and equipment used in the production process, the data and results of product testing, and the production time and personnel of the product in each process.

2.Production quality control

The production process and the inspection process are out of control.100 percent to eliminate the input of defective products, 100 percent to eliminate the outflow of defective products.Any defective product or production abnormality can be provided with good warning through the SFIS system, and it will never allow any abnormal product to continue to develop, and will never allow a defective product to continue to flow into our production line, so that our defective rate and production cost will decline imperceptibly.

3.Transparent production data

Production information collection after SFIS system analysis, can through electronic kanban system report and present at the scene of the production, in the form of production progress, target to achieve status, product quality, and production of man, machine, material utilization, which makes the whole scene completely transparent, enterprise management personnel, through the network can be timely grasp the status of the production site.

4.Intelligent manufacturing

We reduce the participation of personnel through the docking automation equipment and manually adjust this action, so as to generate the unmanned landing operation through automation;Finally, SFIS system can cooperate with automatic equipment to guide production, improve efficiency and quality, and improve the technological content of manufacturing process.Move towards industry 4.0, build intelligent manufacturing factory.

。

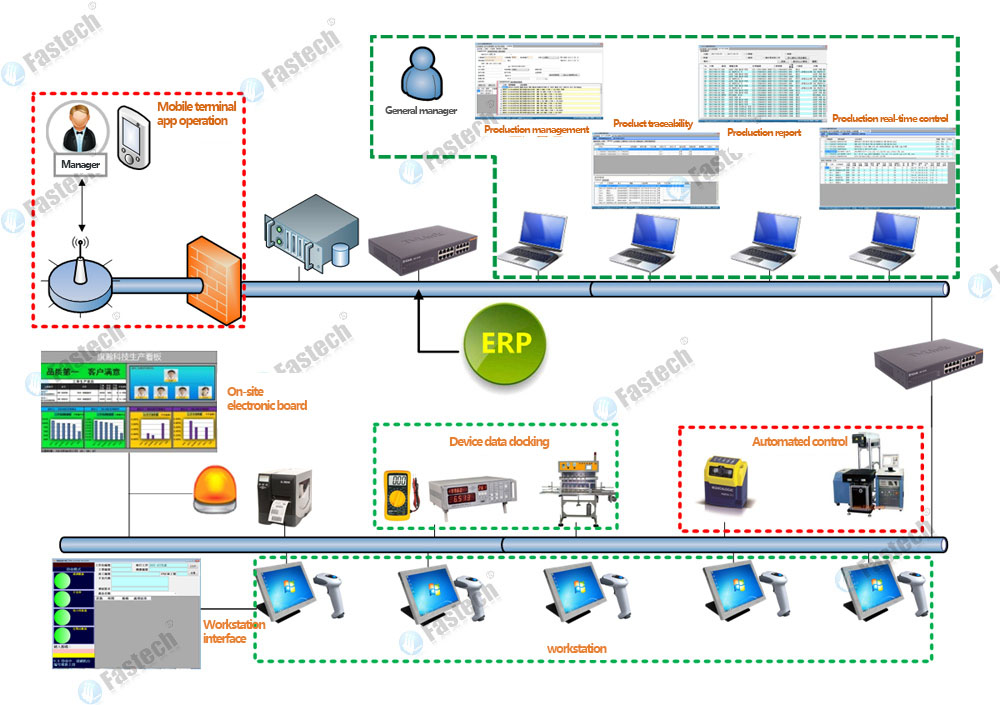

三、SFIS system architecture

四、SFIS operational processes

五、SFIS system benefits

1) reflect the field production status in real time: accurately master the production schedule of the work order and the defect rate, production capacity and progress of each process to increase the capacity utilization rate and improve the delivery accuracy;

2) completely paperless operation on site, without paper and filling, to simplify the management process;

3) the prevention of stay is implemented in every link, and it is easy to master real-time ability and training by using electronic equipment;

4) 100% manufacturing process control and 100% product inspection, with no dead end;

5) easy to adjust the manufacturing process and working group, convenient to dynamically adjust the capacity, quick line change, suitable for the production of a small number of diverse work orders;

6) review of defective reduction heavy industries: make statistics on the causes of defects, and provide early warning of defective products to reduce heavy industries in the process of production;

7) provide customer complaint tracing, trace inquiry of possible defects of materials, processes, equipment, employees and design.